The modern world is no stranger to technological advancements, and laser welding machines are a prime example of this. As the name suggests, these machines use lasers to heat up and fuse metals together with incredible precision.

This makes them an invaluable tool for many different industries – from automotive manufacturing to aerospace engineering – as well as for hobbyists looking to make repairs or create custom projects. In this guide, well explore all aspects of mastering the art of fusion through modern laser welding machines.

Well look at the various types available on the market today and what features they offer; how best to prepare your materials; safety tips for working with powerful machinery; and more. Get ready to take your welding skillset into the 21st century!

Introduction to Laser Welding Machines

Well also discuss the various options available and give tips on choosing the right machine for your needs. By following our advice, you will be well-equipped with all the information necessary to make an informed decision when selecting a laser welder.

Get ready to master the art of fusion with this comprehensive guide!

Understanding the Components of a Laser Welder

A laser welder is a complex and versatile machine that can be used to join two or more pieces of metal together. The success of the welding process depends upon understanding all the components that make up a laser welder.

A laser welder is a complex and versatile machine that can be used to join two or more pieces of metal together. The success of the welding process depends upon understanding all the components that make up a laser welder.

Knowing how these elements interact with one another and how they influence the quality of the weld will help you create strong, consistent results every time. The three main components of any laser welder are: light source, optics, and power supply.

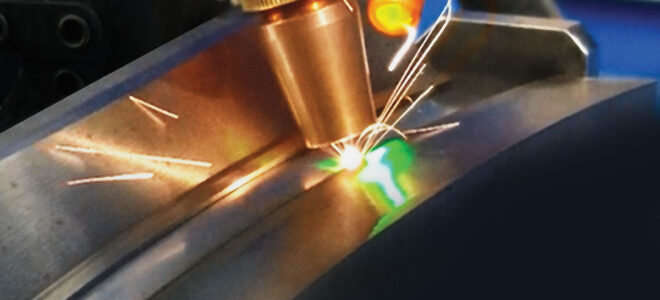

The light source emits high-intensity coherent light which is then focused by optics onto the workpiece material being welded. This focused beam vaporizes or melts away some material from both pieces being joined creating a joint between them in just fractions of a second.

A power supply provides energy to generate this intense heat allowing for precise control over welding parameters such as speed, temperature, pulse widths etcetera. All these variables must be properly balanced in order to produce an optimal result each time while also taking into account environmental factors like air pressure and humidity levels at work site locations.

Its important to understand not only what makes up your laser welder but also what happens when its put into action; ensuring that you are familiar with all aspects involved allows for greater precision when using this powerful tool – ultimately leading to higher quality welds!

Selection and Optimization of Process Parameters

The selection and optimization of process parameters is the key to successful laser welding operations. With a range of available techniques and materials, its important to understand the variables that influence their use.

These include power output, pulse duration, beam intensity, beam spot size, focus depth and working distance. By considering each parameter carefully in relation to the material being welded and its application or purpose, it can be possible to achieve consistent results with minimal distortion or damage.

Its also essential that proper safety protocols are observed when working with high-powered lasers. Once all these factors have been taken into account, an appropriate welding strategy can then be determined for optimal efficiency and quality outcomes.

Conclusion

Laser welding machines are the perfect tools for mastering the art of fusion. They provide a precision that is unrivaled by other methods, and their versatility makes them suitable for use in a variety of settings.

Laser welding machines are the perfect tools for mastering the art of fusion. They provide a precision that is unrivaled by other methods, and their versatility makes them suitable for use in a variety of settings.

With this extensive guide to modern laser welding machines, you now have all the knowledge necessary to make informed decisions on which machine best fits your welding needs. Investing in one will give you unparalleled control over your work and allow you to take it to new heights.