Steel casting is a centuries-old practice in the car manufacturing industry. But, with advancements and innovations in technology over recent years, steel casting has become ever more complex. From highly detailed parts to robust and efficient components, steel casting is now used for many different purposes within the automotive sector.

In this article, we’ll explore how steel casting has evolved and discuss some of the potential new applications it could bring for car manufacturers in the future. Well also look at some of the advances in technology that have enabled these changes as well as consider what challenges remain ahead before these technologies can be fully realized. Ultimately, by understanding this rapidly changing field of engineering we can gain insight into how cars are made today – and tomorrow!

Challenges Present with Steel Casting in the Auto Industry

The automotive industry is no stranger to the challenges posed by steel casting. Despite its widespread use and advantages, there are inherent drawbacks that manufacturers must be aware of when utilizing this method for car production. One key issue is cost: a large part of the process can be time-consuming and costly if not managed properly. Additionally, poor design decisions can complicate the steel casting procedure, leading to extensive delays in production times or even an inability to complete parts correctly.

Other potential issues include improper maintenance which can lead to corrosion or rusting over time as well as errors made during tooling operations resulting in faulty parts being produced. Furthermore, safety considerations must also be taken into account due to the high temperatures required for successful steel casting – these conditions could potentially create hazardous working environments if not adequately monitored and controlled by operators. Despite these setbacks however, advancements such as 3D printing technologies have allowed companies more control over their production processes while providing a viable alternative for those seeking greater efficiency from their manufacturing techniques – making it easier than ever before for automakers to capitalize on both quality and cost savings through this invaluable resource.

Innovations and Advancements in Steel Casting Technology

Source: web-assets.bcg.com

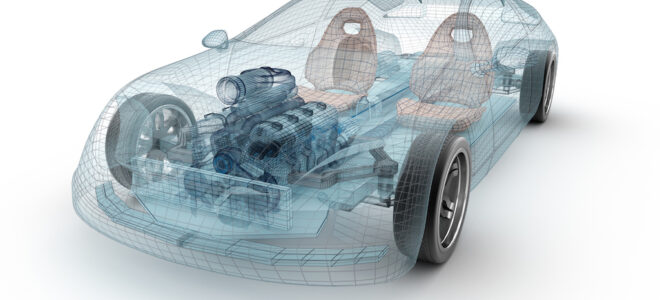

Steel casting technology has come a long way in the past few decades. From single-piece castings to complex assemblies, advances in steel casting have enabled car manufacturers to create lighter and stronger vehicles with greater precision. Innovations such as 3D printing, computer-aided design (CAD), and robotic automation are revolutionizing the industry by allowing engineers to produce components faster and more efficiently than ever before.

In addition, new materials such as carbon fiber composites are being used for high-strength parts that reduce weight without sacrificing strength. As these advancements continue, automakers can look forward to improved performance, fuel economy, and reduced emissions from their vehicles. With so many possibilities on the horizon, it is clear that steel casting will remain an integral part of modern car manufacturing for years to come.

Future Outlook on the Use of Steel Casting in Automobile Production

The future outlook on the use of steel casting in automobile production looks promising. As the demand for vehicles continues to rise, manufacturers are looking for new and efficient ways of producing them with high-quality components. Steel casting is proving to be an ideal solution as it allows car makers to produce complex components quickly and cost-effectively.

With advancements in technology, steel castings can now be produced with greater precision than ever before, making them a viable option for producing car parts such as doors, frames, and bumpers. Additionally, innovations in materials make steel castings even more durable and reliable than before. This not only ensures that cars are built stronger but also helps reduce the time required for maintenance or repairs. As this trend continues, we can expect further developments in steel casting techniques which will enable manufacturers to produce lighter yet sturdier cars at lower costs.

Source: afsinc.org