The automotive manufacturing industry is undergoing an unprecedented transformation with the introduction of laser cutters. These cutting-edge tools are revolutionizing the way goods and parts are being produced for cars, trucks, and other vehicles.

Laser cutters provide a level of precision that was previously thought impossible in automotive manufacturing. With their ability to create intricate designs with incredible speed and accuracy, they can drastically reduce production time while increasing overall quality.

The Laser Edge: Redefining Automotive Manufacturing with Laser Cutters unveils the potential of this technology in reshaping how automobile parts are designed and manufactured. Discover how laser cutters have become a game changer in this sector by exploring its advantages over traditional methods as well as its application to various production processes.

Learn about future developments on the horizon, from advanced materials processing techniques to increased automation capabilities – all thanks to lasers!

Laser Cutting Revolutionizing Automotive Manufacturing

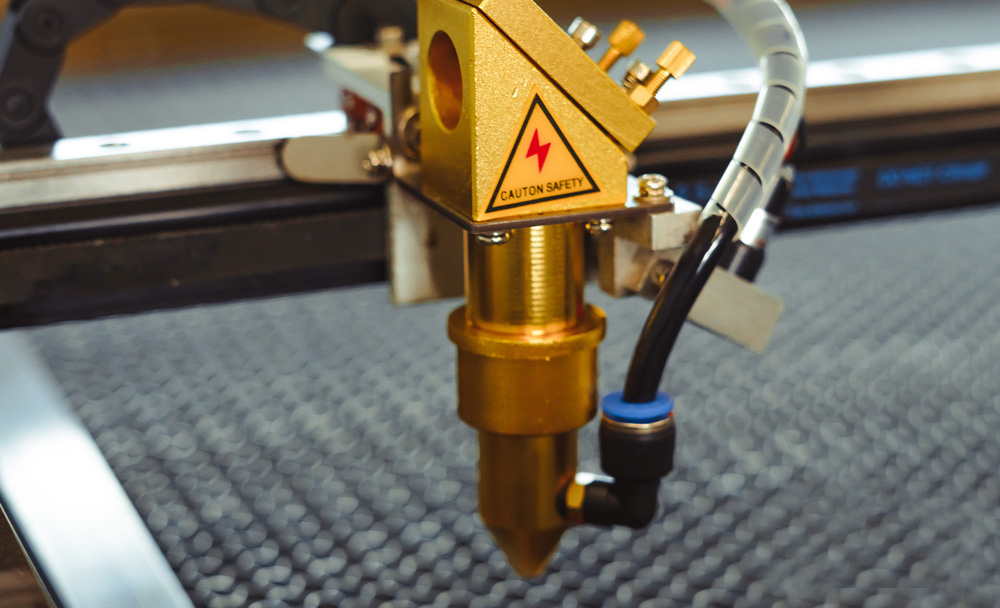

Source: otegotextile.com

The automotive industry is undergoing a revolution with the introduction of laser cutting technology. Laser cutters have become an essential tool for car makers, allowing them to create intricate shapes and precision parts that were never before possible.

From intricate interior trims to complex engine components, laser cutters are transforming how cars are designed and manufactured.The speed at which these machines can work is remarkable, able to produce thousands of perfect cuts in mere minutes.

This has enabled manufacturers to produce more complex designs faster than ever before – meaning that car production times have been drastically reduced without sacrificing quality or accuracy. Not only does this save time and money for companies but it also allows consumers access to higher-quality vehicles sooner than ever before.

Moreover, the flexibility of laser cutters gives designers unprecedented freedom when creating their models; they can craft almost any shape imaginable from metal plates with ease – something that was previously impossible with traditional methods such as stamping or milling machines due to their limited range of movement. With greater design capabilities come innovative solutions – resulting in lighter yet stronger cars for consumers who expect superior performance from their vehicles today.

In short, the use of laser cutting technology in automotive manufacturing is truly redefining what’s possible in vehicle design and production – bringing us one step closer towards self-driving cars while maintaining high standards of safety, comfort and style!

Unlocking the Potential of Laser Cutters in Automotive Production

Laser cutters have revolutionized the way automotive production is done. By allowing for greater precision in cutting components, laser cutters are able to complete jobs faster and with fewer errors than traditional manufacturing methods.

This has enabled automakers to produce parts more quickly and accurately, leading to a reduction in the cost of production. Additionally, laser cutters can be used to create complex shapes that would otherwise be impossible or too difficult with other tools.

This opens up new possibilities for manufacturers and allows them to design ever more intricate car parts which improves performance while keeping costs low. Furthermore, laser cutter technology is also making it easier for companies to customize their products as it can easily handle different materials such as plastics or metals of various thicknesses and shapes.

The potential of this technology has yet to be fully realized but its already clear that laser cutters are changing the landscape of automotive manufacturing by providing an efficient and cost-effective way to produce high-quality components quicker than ever before.

Harnessing the Power of Lasers for Enhanced Quality and Efficiency in Auto Manufacturing

Source: www.thefabricator.com

Laser technology is revolutionizing the auto manufacturing industry, allowing automotive businesses to produce top-tier products with unparalleled efficiency and quality. Laser cutters are able to shape metal into intricate designs with extreme precision, making them ideal for producing custom parts that could not be achieved through conventional cutting methods.

As a result, manufacturers can create higher quality components while simultaneously reducing production costs and time spent on each product. The use of lasers in auto manufacturing has also increased safety standards across the industry by greatly reducing human contact during the cutting process. With laser cutters doing most of the work, employees are kept at a safe distance from sharp objects and hazardous materials while still ensuring that each part meets high standards of accuracy.

This minimizes potential exposure to injury or illness due to workplace accidents as well as improves overall job satisfaction among workers who no longer have to worry about being close to dangerous machinery during their shifts. In addition, laser technology can help reduce waste associated with traditional cutting methods such as sawing or grinding which often require large amounts of material for setup or leave behind excess scraps when finished.

By using more precise tools like laser cutters, manufacturers can maximize output without sacrificing any needed resources while ensuring that every component produced meets exact specifications without fault or errors in measurement. The power of lasers is transforming how automotive companies design and manufacture their parts — creating opportunities for enhanced quality control and cost savings all in one fell swoop! The use of this revolutionary technology has allowed businesses around the world to take advantage of its incredible benefits both now and into the future — ultimately redefining what it means for an automobile manufacturer to succeed in todays competitive market!

Conclusion

Source: www.madearia.com

The use of laser cutters to redefine automotive manufacturing is an exciting development that will revolutionize the industry. With their high precision and accuracy, laser cutters allow for faster production times while still achieving top-tier results.

Thunder Lasers cutting edge equipment is a prime example of how this technology can be used in the automotive manufacturing process, allowing for greater efficiency and improved product quality. This new approach to creating vehicles promises more efficient production as well as better overall performance from its components, making it a winning solution for all involved.