The automotive industry is always on the lookout for new technologies that can help them cut costs and increase efficiency; one of the most effective solutions to this problem has been laser cutting. Laser cutting is a precise, fast, and efficient method of making cuts in materials such as metal, glass, plastic, and wood.

This article will discuss what makes laser cutting so effective in automotive production processes and how it has revolutionized the way automakers manufacture their vehicles. We’ll examine the wide range of advantages offered by laser cutting technology, from cost savings to improved accuracy and speed.

Finally, we’ll take a look at some of the key considerations when looking into incorporating laser-cutting systems into your production line.

Understanding How Laser Cutting Works in the Automotive Industry

Source: www.asme.org

Understanding how laser cutting works in the automotive industry requires a deep understanding of both its advantages and limitations. Laser cutters are capable of producing precise, intricate designs with minimal waste – far more quickly than traditional cutting methods.

They also generate less heat and noise during operation, making them much safer to use than other metal-cutting tools. Furthermore, laser cutters require less maintenance due to their superior durability when compared to other machines.

Despite these advantages however, certain drawbacks need to be taken into consideration before implementing this technology within an automotive production line; such as energy consumption levels which can be quite high at times depending on the type of material being worked with or the complexity involved in each project – along with potential hazards related to eye damage from exposure if safety measures are not properly implemented throughout various stages associated with working on specific parts shortly after they have been processed by lasers too!

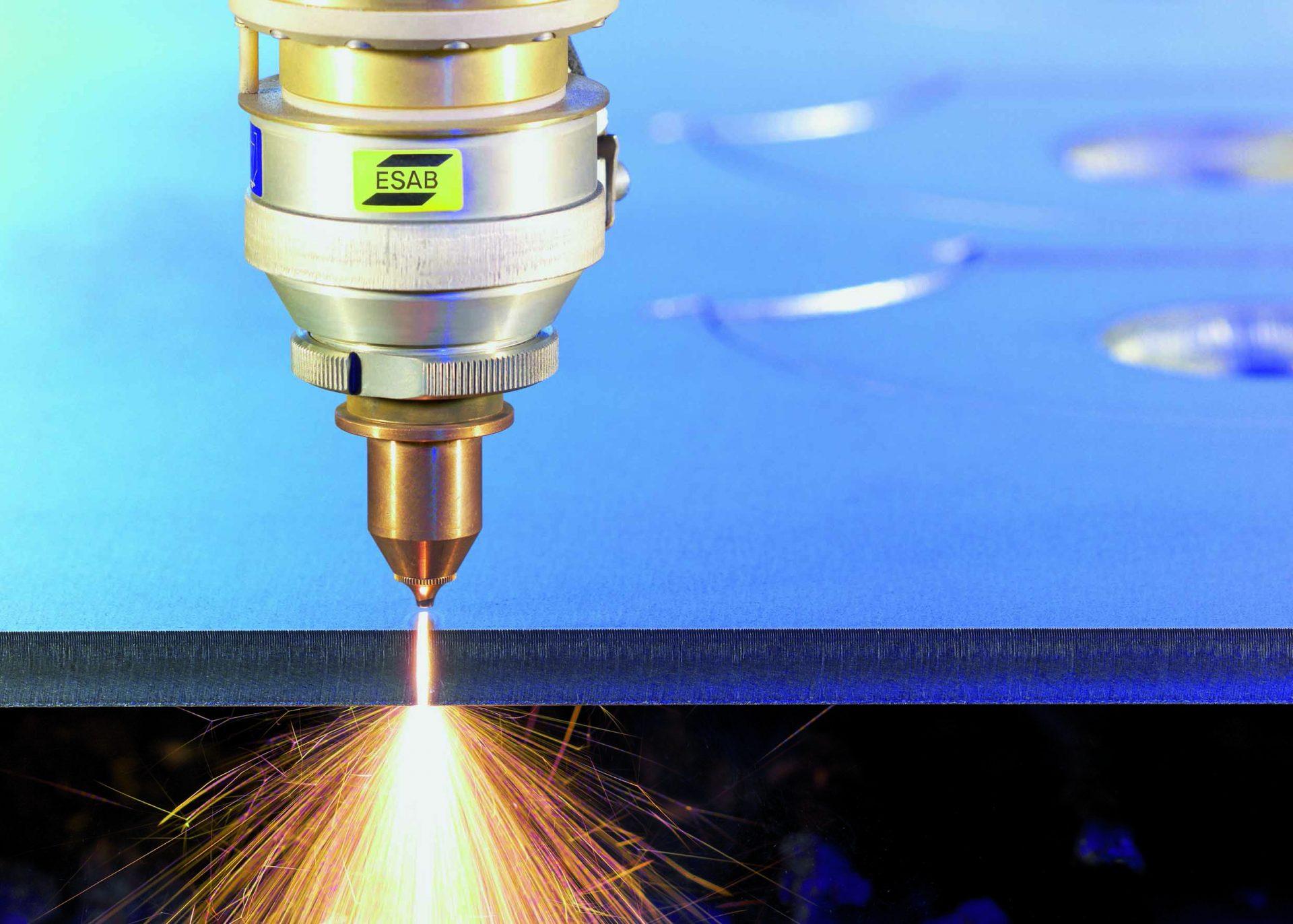

Exploring the Advantages of Laser Cutting

Source: esab.com

Exploring the advantages of laser cutting in the automotive industry unlocks a new level of production efficiency and accuracy. Laser cutters are capable of producing intricate shapes with minimal material waste, while also providing a high level of precision and repeatability.

This reduces labor costs associated with longer operating times, as well as reducing hazardous environments due to less manual intervention needed for specific applications required by certain projects.

Additionally, lasers do not need tool changes between cuts like mechanical systems do; this helps reduce human intervention thus eliminating potential safety hazards from manual operations along with errors caused by improper settings or incorrect operating procedures when changing tools manually between processes – resulting in higher tolerances that lead to greater consistency throughout production runs regardless of scale size or complexity involved in each project.

Finally, because of its speed and efficiency when compared with other manufacturing processes such as punch presses or manual saws; not only do production times drop significantly but so do labor costs associated with producing parts via automated machining techniques.

The Efficiency and Precision that Comes with Laser Cutting Technology

Laser-cutting technology has become an increasingly popular method for automotive parts manufacturing because of its efficiency and precision. The laser beam used in this process allows for precise and intricate cuts that would otherwise be difficult to achieve with traditional mechanical cutting tools.

Laser cutting also saves time by allowing multiple pieces of material to be cut at once, which is especially beneficial when there are many complex shapes or designs needed. Additionally, the heat generated from the laser beam seals edges as it cuts, ensuring a clean finish on each part produced.

With its combination of speed, accuracy, and cost-effectiveness, laser cutting technology offers an invaluable tool for automotive industry professionals looking to save both time and money while creating quality products.

Source: twi-global.com

Modernizing Production Processes

The automotive industry has seen an uptick in the use of laser cutting technology as a way to modernize their production processes. This cost-effective technology eliminates the need for manual labor and traditional metalworking tools, allowing factories to produce more parts with greater efficiency and accuracy.

With powerful lasers able to cut into hard metals at high speeds, laser cutting offers a range of benefits that help automakers reduce costs and improve quality control. Laser cutters can work on intricate details with precise measurements that are nearly impossible for workers or machines using other methods.

Conclusion

Source: dienamics.com.au

Laser cutting is an effective and efficient way to produce components for the automotive industry. It has become increasingly popular due to its precision, speed, and cost savings compared to other cutting methods.

Laser cutters are capable of producing intricate shapes with minimal material waste while also providing a high level of accuracy and repeatability. The use of a laser cutting machine in the automotive sector provides manufacturers with faster turnaround times, higher quality parts, improved safety standards, and decreased operating costs.

This makes it one of the most sought-after solutions for many automotive production facilities today.